The production process of brake pads

发布日期:2018-03-26 浏览次数:784

1, Raw material blending: basically consists of steel fiber, mineral cotton pads, graphite, wear-resisting agent, resin and other chemicals, and the size of the friction coefficient, wear index and noise value, it is through these materials to adjust the proportion of allocation.

2. Back plate treatment: cleaning, surface cleaning of steel parts, clean without oil;Shot blasting is to make the steel back surface to meet certain roughness requirements;Pay attention to the thickness and the cover rate;No residue on the surface.

3. Hot forming stage: pour the mixture into the mold, and press the pressure to form, so that the two can be combined more closely.The brake pads are in the oven, and the porcelain can be heated for up to 6 hours before it can be processed.

4. Grinding and cutting stage: after heat treatment, the brake plate has a lot of rough edges, so it needs to be ground and cut to make it smooth.

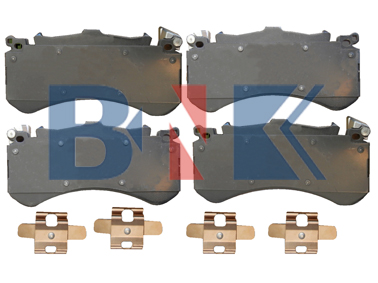

5. Grooving and chamfering: the cutting groove can add friction, heat dissipation, dust removal, etc.Use the straight-line grinding machine to cut the slot and chamfer, and pay attention to the thickness and the plane of the grinding surface.6. Spray painting stage: to avoid the rust of iron material and achieve a beautiful effect, it is necessary to work with spray painting.Electrostatic spraying (powder: flat light powder, sand grain powder) : the spray powder should pay attention to electrostatic voltage, drying temperature and baking time, and pay attention to the coating thickness, evenness and coating cover rate.

7. Transfer printing and spray code: spray code on the side and back of the powder block, pay attention to the position, size, adhesion and sharpness of the spray code;

Accessories installation: accessories assembly (riveting;Adhesion) : pay attention to convex nails, positioning holes and positioning slots;The riveting includes the rotary riveting (PAD) and the SHOE.Pay attention to accessories configuration, accessories positioning, accessories firmness and effective alarm length;Pay attention to inspection of alarm, shock absorber, reinforcing block, wire, spring, spring, gasket and other accessories.

Enter the color box, carton, packing, wooden support and other follow-up work.

Mail:sale2@bnkauto.net

Skype:tzjj0807@hotmail.com

Mobile:(86) 13721205761